Electronic universal testing machine

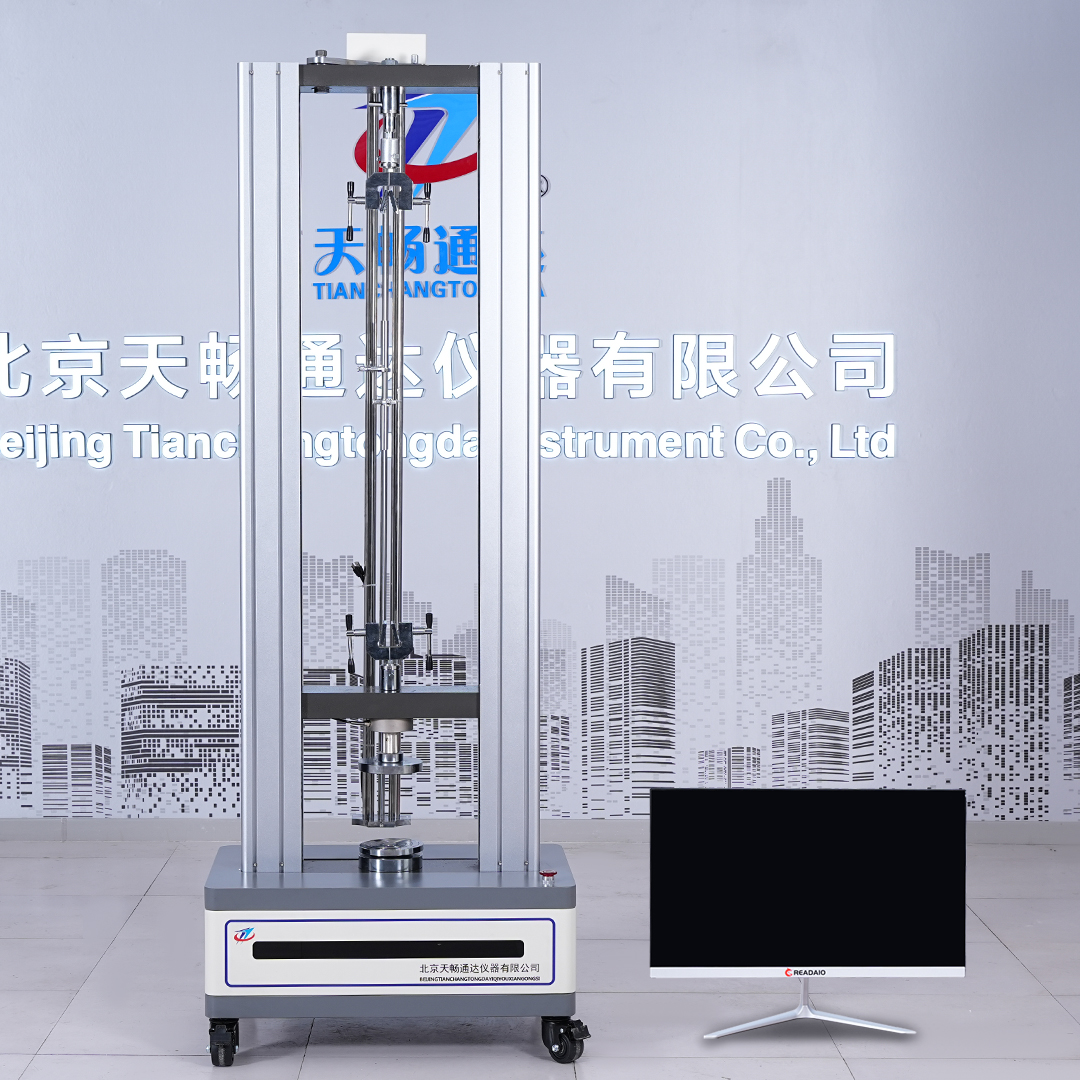

PIC-(Electronic universal testing machine)

1、 Product Overview

Electronic universal testing machine is a high-precision and multifunctional material testing equipment. It adopts advanced mechatronics design, combined with modern electronic technology and computer technology, aiming to comprehensively test the mechanical properties of various materials. The electronic universal testing machine plays an important role in multiple fields such as material research, product development, and quality control due to its excellent performance, diverse testing functions, and user-friendly operating interface.

2、 Product appearance and structure

The appearance design of the electronic universal testing machine is simple and modern, and the overall structure is sturdy and stable. The body is usually made of advanced stainless steel material, which has good corrosion resistance and durability. The surface of the equipment is finely treated, which not only looks beautiful and elegant, but also effectively resists the erosion of the external environment.

The structure of the testing machine mainly includes loading frame, transmission system, measurement system, and control system. The loading frame is the main structure of the testing machine, which bears all the loads during the testing process. The transmission system achieves a smooth loading and unloading process through high-precision servo motors and reducers. The measurement system adopts high-precision sensors and data acquisition cards to ensure the accuracy and reliability of experimental data. The control system is the brain of the entire testing machine, responsible for precise control and monitoring of the testing process.

3、 Function and Features

Multifunctionality: The electronic universal testing machine has various testing functions such as tension, compression, bending, shearing, tearing, peeling, etc., which can meet the testing needs of different materials. Users can choose appropriate fixtures and accessories according to specific test requirements, easily achieving various complex mechanical performance tests.

High precision measurement: The testing machine adopts high-precision force sensors and displacement sensors, which can monitor and record real-time force values, displacement and other data during the testing process. Combined with advanced data processing algorithms, key indicators such as elastic modulus, yield strength, and tensile strength of materials can be accurately calculated.

Powerful control system: The electronic universal testing machine is equipped with high-performance microprocessors and computer systems, achieving full automatic control of the testing process. Users can pre-set test parameters, such as loading speed, test force, etc. The testing machine will automatically complete the test process according to the set program, greatly improving work efficiency and repeatability of the test.

User friendly operation interface: The testing machine is equipped with a LCD display screen and user-friendly operation software, allowing users to intuitively view test data and curves, and conveniently set parameters and export data. The operating software also supports multiple languages, making it convenient for users from different countries and regions to use.

Safety protection measures: The electronic universal testing machine has multiple safety protection measures, such as overload protection, limit protection, etc., to ensure the safety and reliability of the testing process. When abnormal situations occur during the testing process, the testing machine will automatically shut down and issue an alarm, effectively protecting the safety of operators and equipment.

4、 Advantages and Working Principles

The advantages of electronic universal testing machines lie in their high precision, multifunctionality, and intelligent control. These advantages enable the testing machine to meet the mechanical performance testing needs of various complex materials, providing strong technical support for researchers and engineers. At the same time, the user-friendly design and security measures of the testing machine greatly reduce the difficulty and risk of operation.

In terms of working principle, the electronic universal testing machine mainly drives the transmission system through a servo motor to achieve loading and unloading of the sample. The measurement system monitors the force and displacement data in real-time during the testing process and transmits these data to the control system for processing. The control system precisely controls and adjusts the experimental process based on preset experimental parameters and algorithms, ensuring the accuracy and repeatability of the experiment.

5、 Product composition

The electronic universal testing machine mainly consists of the following parts:

Host: includes core components such as loading framework, transmission system, and measurement system, responsible for executing loading, unloading, and measurement tasks during the testing process.

Control system: composed of microprocessors, computers, and related circuits, responsible for controlling the operation and data processing of the testing machine.

Fixtures and Accessories: Provide various fixtures and accessories according to different testing requirements, such as stretching fixtures, compression fixtures, bending fixtures, etc., to meet the testing requirements of various materials.

Operation software: Provides an intuitive user interface and powerful data processing functions, making it convenient for users to set experimental parameters, view data, and export operations.

6、 Instrument technical parameters

The following are some main technical parameters of the electronic universal testing machine:

Accuracy level: High precision measurements typically up to level 0.5.

Rated load: Depending on the model, the rated load range can range from 1N to several kilonewtons.

Effective force measurement range: usually able to cover 0.1% to 100% of the full range.

Test speed: The adjustable range is wide, ranging from 0.001mm/min to 500mm/min or even higher.

Speed and displacement accuracy: usually within ± 0.5% of the indicated value.

Stress control rate range and accuracy: can be precisely set and adjusted as needed.

For specific technical parameters, please refer to the product manual of each model of electronic universal testing machine or consult the manufacturer for accurate information.

7、 The instrument meets the standards

The electronic universal testing machine strictly follows national and international standards in its design and production process to ensure the accuracy and reliability of its performance and measurement results. Common compliance standards include but are not limited to: GB/T, ISO, ASTM, etc. Users should choose testing machines that comply with relevant standards and certifications when purchasing to ensure the legality and validity of test results.

8、 Application field

Electronic universal testing machines are widely used in multiple fields, including but not limited to:

Research on Metal Materials: Testing the mechanical properties of metal materials such as tension, compression, and bending, providing data support for material development and process optimization.

Plastic and Rubber Industry: Evaluate the mechanical properties of plastic and rubber products, such as tensile strength, elongation at break, etc., to ensure product quality and performance.

Textile and paper testing: testing the tensile strength, tear strength, and other indicators of textiles and paper, providing a basis for product development and quality control.

Composite material research: Conduct various mechanical performance tests on composite materials to evaluate their structural strength and durability.

Automotive and aerospace fields: testing the mechanical properties of components and materials to ensure the safety and reliability of products under extreme conditions.

9、 Scope of application and limitations

The electronic universal testing machine is suitable for testing the mechanical properties of various solid materials, including but not limited to metals, non-metals, composite materials, etc. However, there are also some limitations that need to be noted during use:

Sample size and shape: Testing machines usually have certain requirements for the size and shape of samples, and users need to select suitable samples for testing based on the specifications of the testing machine.

Temperature range: Some testing machines may work best within a specific temperature range, and exceeding this range may affect the accuracy of test results.

Maximum load limit: Each testing machine has its rated load range, and testing outside this range may cause equipment damage or inaccurate measurement results.

Operating environment: The testing machine should be placed in a stable, dust-free, and corrosion-free environment to ensure the normal operation and service life of the equipment.

Summary: As a high-precision and multifunctional material testing equipment, electronic universal testing machines play an important role in scientific research, industrial production, and quality control. Its powerful testing functions, high-precision measurement, and intelligent control system enable users to easily complete various complex mechanical performance testing tasks. When selecting and using a testing machine, users should pay attention to factors such as relevant standards and certifications, technical parameters, scope of application, and limiting conditions to ensure the accuracy and effectiveness of test results.