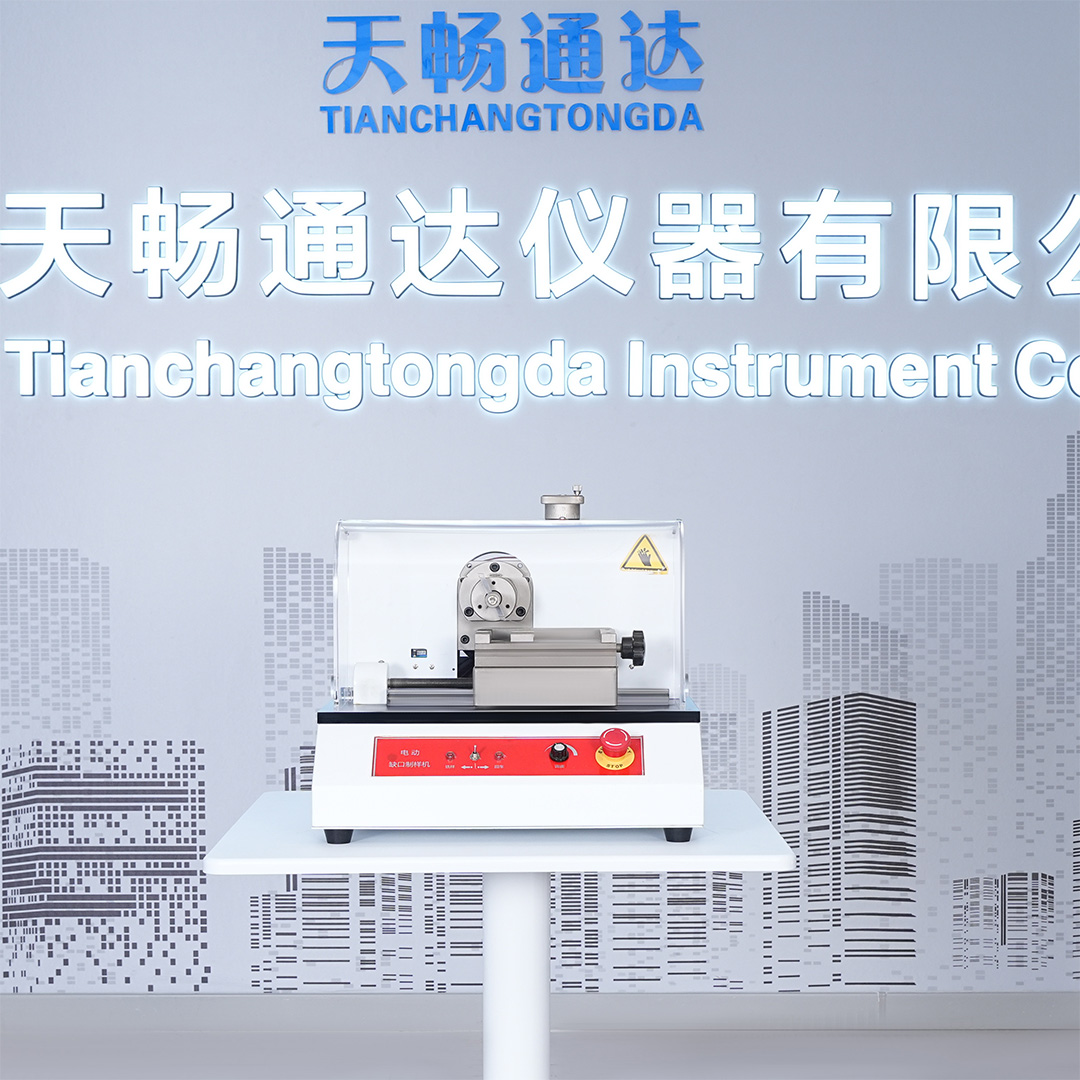

Single gap prototype

PIC-(Single gap prototype)

1、 Product Introduction Single Notch Prototype is a professional equipment used for preparing material performance testing samples. Its core value and characteristics are mainly reflected in precision, efficiency, convenience, and wide applicability. This device can accurately create the required shape and size of notches on material samples according to relevant standards for subsequent mechanical performance testing.

Appearance and structure:

Single notch prototype machines are usually designed as sturdy desktop structures, with high-quality metal materials used for the shell and anti rust paint sprayed on the surface to ensure the stability and durability of the equipment. The operation panel of the device is simple and intuitive, equipped with necessary operation buttons and indicator lights, making it convenient for users to operate and monitor.

Function and features:

1. High precision: The equipment adopts advanced control systems and precise mechanical transmission mechanisms, which can ensure the production of precise sized notches on the sample.

2. Easy to operate: Users only need to place the sample on the workbench of the equipment, set the relevant parameters, and automatically complete the production of the notch.

3. Efficient and fast: The equipment has high work efficiency and can complete the production of multiple sample notches in a short time.

4. Wide applicability: Suitable for notch making of various material specimens, including but not limited to metals, plastics, rubber, etc.

Advantages:

Compared to traditional handmade or other simple equipment methods for making notches, the single notch prototype has the following obvious advantages:

1. Improve accuracy: The mechanized operation method avoids the instability and errors of manual operation, making the notch size of each sample more consistent and accurate.

2. Improving efficiency: The automated operation process greatly shortens the time for sample preparation and improves work efficiency.

3. Enhanced security: avoids the risk of injury that operators may experience during the process of manually making gaps.

Working principle:

The working principle of the single gap prototype is mainly to control the cutting system through an electrical control system to accurately cut according to the preset program. The specific process is as follows:

1. Place the sample to be processed in the sample chamber and fix it securely.

2. Set cutting parameters as needed, such as notch depth, width, etc.

3. Start the device, and the electrical control system will control the cutting tool to move precisely according to the preset program, thereby cutting out the required gaps on the sample.

After the cutting is completed, the equipment will automatically stop and prompt the user to take out the processed sample.

2、 The main technical parameters of a single gap prototype include:

·Tool stroke: 20mm

·Processing notch depth: 0-25mm adjustable

·Workbench stroke: 80mm

·Cutting speed: 70 times/minute adjustable

It should be noted that the above parameters may vary depending on different manufacturers and models of single notch prototypes. Please refer to the equipment's user manual or consult the manufacturer for the most accurate parameter information.

3、 The instrument complies with the standard single notch prototype and strictly follows relevant international and domestic standards in the design and manufacturing process to ensure its performance and reliability. Specifically, the device meets the following standards or certifications:

·ISO 179: Notch preparation requirements for determining the bending properties of plastics.

·ISO 180: Notch preparation requirements for determining the compressive properties of plastics. (Note: ISO 179 and ISO 180 mainly specify the methods and requirements for making specimens using single notch prototypes.)

·GB/T 1043: Requirements for specimen preparation in the method of simply supported beam impact test for rigid plastics.

·GB/T1843: Determination of impact strength of plastic cantilever beams

4、 The single gap prototype is widely used in the field of material performance testing, including but not limited to the following aspects:

1. Metal material testing: In the field of metal materials, single notch prototypes are often used to prepare specimens with notches for mechanical performance testing such as tension, compression, and bending. By testing the performance parameters of these samples, the strength, hardness, plasticity and other characteristics of the material can be understood.

2. Plastic and rubber material testing: In the field of plastic and rubber materials, single notch prototypes are also used to prepare specimens. By testing these samples, one can understand the material's performance parameters such as tensile strength, compressive strength, and elastic modulus.

3. Research and education: In research institutions and universities, single gap prototypes are often used in teaching and experimentation of material performance research. By preparing standard specimens and conducting tests, students and researchers can better understand the properties and behavior of materials.

4. Quality inspection and control: In industrial production, single gap prototypes are also commonly used in product quality inspection and control. Ensure that the produced materials or products comply with relevant standards by preparing and testing samples

5、 Scope of Application and Limitations Scope of Application:

1. Material type: Single notch prototype is suitable for various types of materials, including metal, plastic, rubber, composite materials, etc. These materials can be precisely made into the desired shape and size of notches through this device.

2. Sample size: The equipment is usually able to adapt to a certain range of sample sizes. Users can choose the appropriate sample size based on the specific device specifications.

3. Gap type: According to testing requirements, the single gap prototype can produce different types of gaps, such as V-shaped, U-shaped, etc. These types of gaps can meet different testing standards and methods.

Limitations:

1. Sample thickness limitation: Although single notch prototypes can handle samples of different thicknesses, there is usually a maximum sample thickness limitation. The user needs to ensure that the sample thickness is within the specified range of the equipment.

2. Material hardness limitation: For materials that are too hard or too soft, a single notch prototype may not be able to produce precise notches. Therefore, it is necessary to confirm whether the material hardness is within the processing range of the equipment before use.

3. Operating environment: In order to ensure the normal operation of the equipment and extend its service life, the single gap prototype needs to be used in a dry, ventilated, and dust-free environment, and avoid direct sunlight and high temperatures.

6、 Operation precautions 1 Before operation, be sure to carefully read the user manual of the equipment and ensure that you understand all operating steps and safety precautions.

2. During the operation, it is necessary to wear appropriate protective equipment, such as gloves, goggles, etc., to prevent possible injuries.

3. Ensure that the specimen is correctly fixed on the workbench to prevent movement or detachment during the cutting process.

4. Select appropriate cutting parameters based on the material and thickness of the sample to achieve the best cutting effect.

During the operation, if any abnormal situations or equipment malfunctions are found, the operation should be stopped immediately and professional personnel should be contacted for maintenance.

Through the detailed introduction above, we can understand the important role of single notch prototype in material performance testing, as well as its core value and characteristics. This device not only improves the accuracy and efficiency of sample preparation, but also provides convenient and reliable tools for scientific research, education, and industrial testing.