Pipe static hydraulic testing machine JYY - (3-12)

PIC-(Pipe static hydraulic testing machine JYY - (3-12))

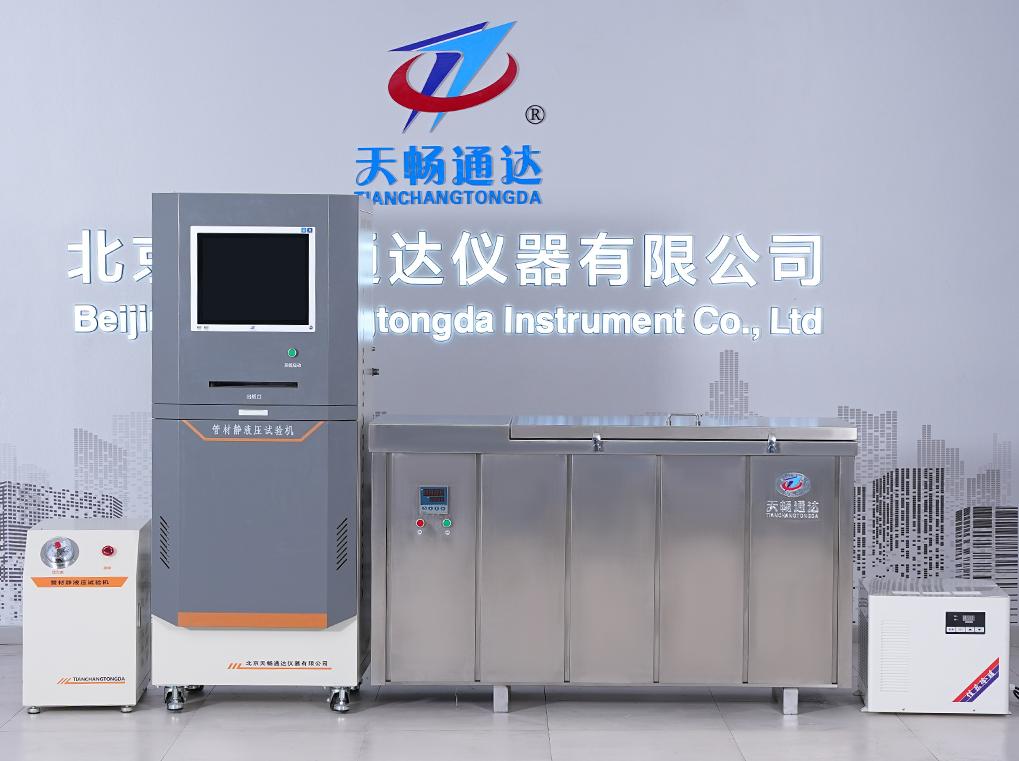

Overview

1. This instrument has been developed in accordance with the requirements of GB/T 6111-2018 and GB/T 15560-1995 standards

A testing machine used to maintain the long-term internal pressure resistance of pipes or fittings within a certain pressure range. It automatically stops after the tested pipes or fittings rupture or are completed, and can save the pressure curve and print the test report. In terms of control, pressure replenishment and relief are controlled by the opening of the pressure replenishment and relief solenoid valves. The stable control of pressure is mainly achieved by the inching opening of the pressure replenishment and relief solenoid valves. This testing machine has functions such as automatic constant pressure, electric pressure relief, cleaning, and automatic calibration. The instrument uses imported electromagnetic valves from the United States, with a unique sealing structure, ensuring the sealing and durability of the electromagnetic valves when the water quality is clean. Due to sudden power outages or human operation causing computer crashes, Our company's pressure host can provide long-term data storage and downloading, reducing the workload of workers. It is an economical, practical, multifunctional, and highly automated testing machine.

2. This instrument consists of a pressure host, a pressure station, a water tank, a temperature control system, and a computer software system

Group. Pressure host: It consists of a pressure micro control part, an automatic pressure compensation and electric pressure relief part. The pressure micro control part adopts microcomputer control, equipped with high-resolution and high-speed calculation modules, and communicates with the computer in real-time. It can automatically supplement and relieve pressure according to the pressure situation.

Pressure station: Its main function is to provide pressure to the pressure host. The pressure requirement of the pressure station is that the lower limit must be higher than the pressure of all samples tested. This section uses an imported plunger pump from the United States, which has high flow rate, low noise, high pressure, and is maintenance free. Through an external high-pressure hose, it can automatically replenish water, ensuring the reliability of the total pressure and becoming the most reliable pressure source.

Water tank: composed of a circulation section, a heating section, an automatic water replenishment section, and an insulation section. The circulation section uses a high flow pipeline pump to ensure uniform temperature in the water tank and fast temperature exchange.

Temperature control system: Precisely control the temperature of the water tank, display the temperature, set the temperature separately, and intelligently control the liquid level of the water tank, ensuring that the temperature is maintained and the liquid level is at a reasonable position..

Software system: Connected to the pressure host through RS232 serial interface, it provides various functions such as parameter setting, calibration, pressure relief, zero adjustment, amplitude adjustment, drawing of test curves, saving test records, and printing test reports.

3. Application field

This instrument is widely used in the internal pressure test of various plastic pipes and is an ideal testing equipment for the building materials industry, pipe production units, national testing departments, and scientific research units. This instrument adopts an intermittent pressure replenishment method, with stable pressure and large flow rate, which can meet the testing conditions of various caliber pipes. It can completely replace imports and is a product with simple operation and excellent performance. The product is exported to the international market and is in good use.

4. The instrument complies with the standard GB/T 6111-2003 "Resistance to Damage of Thermoplastic Pipes under Long Term Constant Internal Pressure"

Method for determining time GB/T 15560-1995 "Hydraulic instantaneous burst and pressure test method for plastic pipes for fluid transport"

Main technical parameters

System working pressure 10MPa

Pressure accuracy -1% -2%

Temperature control range of constant temperature water tank: high and low temperature water tank: room temperature~95 ℃ or 20-95 ℃ (optional)

Timer working time 0-10000 hours

Timing error ± 0.1%

Pressure host 220V 2KW

Pressure station 380V 1KW

Host size 840mm * 810mm * 1900mm

Booster pump size: 680mm * 470mm * 710mm

Refrigerator size 670mm * 590mm * 490mm