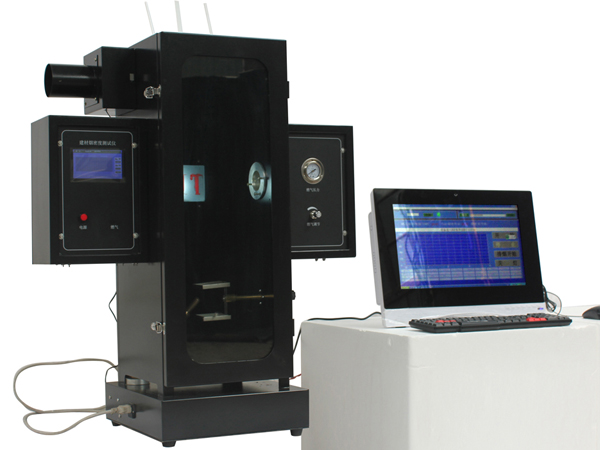

Touchscreen computer dual control building material smoke density tester

PIC-(Touchscreen computer dual control building material smoke density tester)

1) Applicable scope

The touch screen computer dual control building material smoke density tester is developed according to the technical conditions specified in the national standard GB/T8627-2007 "Test Method for Smoke Density of Combustion or Decomposition of Building Materials", and is suitable for the determination of static smoke production during combustion of building materials, their products, and other materials

2) Product functional characteristics

1. Dual control mode, can be controlled on the touch screen or on the computer, and the operation mode can be easily switched! (Users bring their own computers and printers; upper computer software, routers, and network cables will be sent along with the device)

2. A device can be operated by multiple computers simultaneously, and multiple computers can be online simultaneously, achieving LAN sharing!

3. The main and auxiliary burners can rotate automatically and position accurately.

4. Independently developed control programs that can meet various operations, records, time curves, and result calculations in experiments.

3) Related technical parameters

1. For the maximum smoke density (MSD) and smoke density level (SDR) of the specimen: 0-100% continuously measurable, automatically calculated;

2. Use a standard filter to correct for an error of no more than 3%; Each device is equipped with three standard filters, and the data for calibrating the light source is representative

3. Bensheng lamp working pressure (210 ± 5) KPa;

4. Apply flame to the sample using a Bunsen burner for 4 minutes;

5. Combustion lamp: It is a Bunsen lamp with a length of 260mm and a nozzle diameter of 0.13mm, forming a 45 ° angle with the smoke box;

6. Optoelectronic system: The light source is a light bulb, with a power of 15W and a working voltage of 6V;

7. Exhaust system: This machine is equipped with a powerful exhaust fan, which can discharge exhaust gas outdoors after the test is completed;

8. Smoke density measurement range: 0-100%;

9. Accuracy of smoke density measurement: ± 3%;

10. Receiver: It is a silicon photocell, with a light transmittance of 0% indicating no light passing through, and a light transmittance of 100% indicating complete light passing through without obstruction;

11. Working pressure of the main burner: 276KPa (adjustable); (Optional auxiliary burner)

12. Automatic timing, automatic ignition, and automatic smoke exhaust; The linear calibration test of luminous flux can be carried out in stages, which improves the accuracy of the data;

13. Touch screen display:

① Size: 5 inches, effective display size: 11cm in length and 6.28cm in width;

② Resolution: 800 * 480

③ Communication interface RS232, 3.3V CMOS or TTL, serial port mode

④ Storage capacity: 1G

⑤ Using pure hardware FPGA driver display, with "zero" startup time, can run on power

⑥ Adopting the M3+FPGA architecture, M3 is responsible for instruction parsing, FPGA focuses on TFT display, and the main controller adopts a low-energy processor, automatically entering energy-saving mode

14. Gas source: 95% propane gas, or gas of equivalent purity (note: gas source and connecting head are provided by the user);

15. Length * width * height 740 * 500 * height 900 (mm)

4) Work environment

1. Environmental temperature: 0 ℃ -40 ℃;

2. Relative humidity: ≤ 85%

3. Power supply voltage and power: 220V ± 10%, 50HZ, 100W;

4. Gas pressure: 0-0.3MPa (adjustable);

5. Environmental and test requirements: The instrument should avoid direct exposure or reflection of strong light on the instrument during operation; After 90 minutes of testing, the gas source should be turned off to cool the instrument for 15 minutes.

6. Environmental airflow: There is no forced air flow phenomenon during operation;

7. The instrument should be placed in a fume hood for testing;

5) Instrument structure

Divided into two main parts: smoke box and control;

Smoke box section: On the left and right panels of the smoke box, there are power switches, safety sign switches (backlight switches), gas regulating devices, and also switches to control the exhaust fan (fan switch).

6) Applicable standards

Design standard: GB/T8627-2007 "Test method for smoke density of combustion or decomposition of building materials"

Compliant with standard: GB/T8627 ASTM D2843