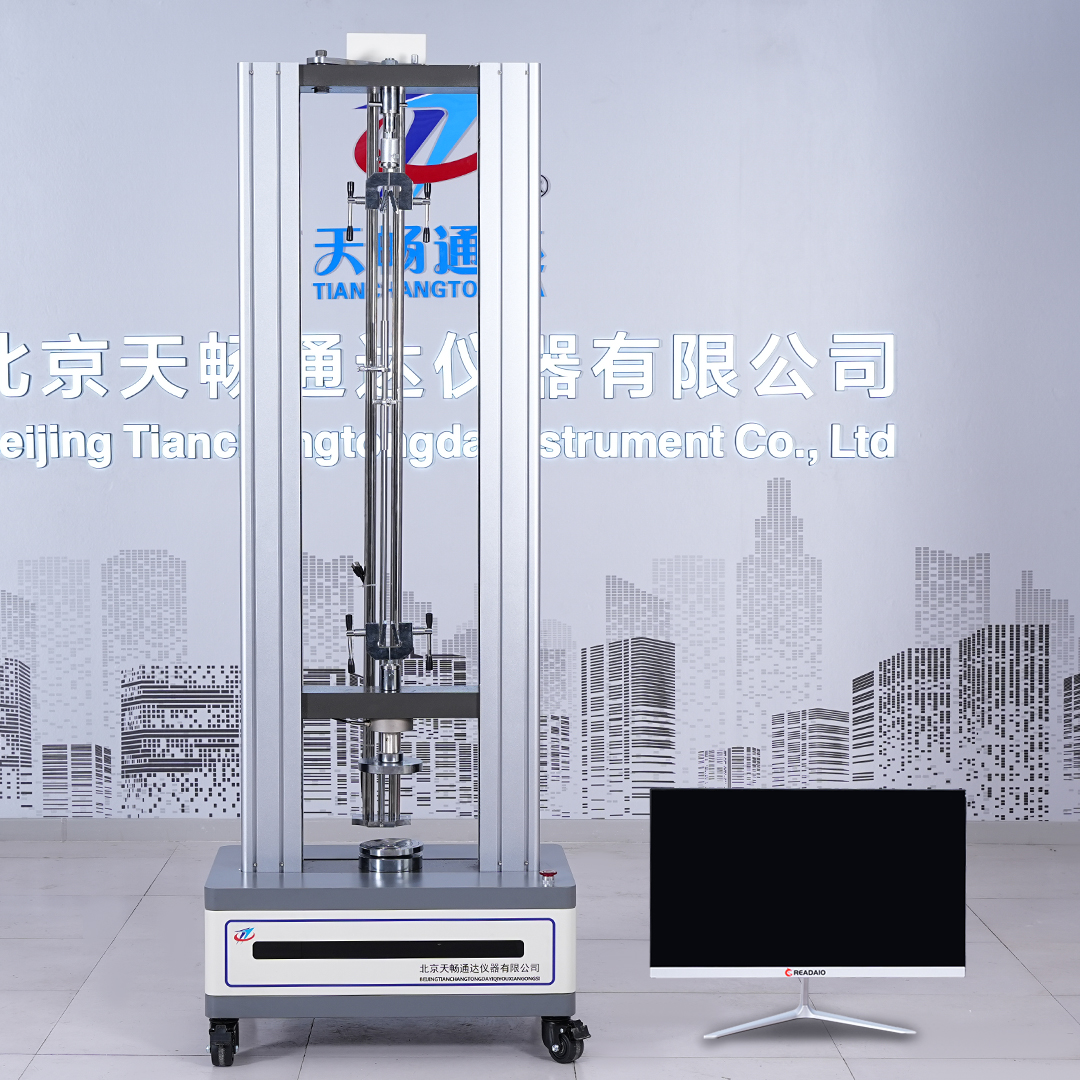

LXZ-200 microcomputer controlled buckle mechanical performance testing machine

PIC-(LXZ-200 microcomputer controlled buckle mechanical performance testing machine)

1、The testing machine meets the following standards

1.Steel pipe scaffold fasteners GB15831-2006

2.Safety Technical Specification for Coupler type Steel Pipe Scaffolding in Construction JGJ 130-2011

3.Determination of Physical and Mechanical Properties of Ropes GB/T8834-2006

4.Safety Net GB5725-2009

5.Bowl Buckle Steel Pipe Scaffolding GB24911-2010

2、Mechanical structure

This testing machine consists of four pillars and two precision ball screws that fix the upper crossbeam and worktable.It uses an AC servo motor and driver to drive two pairs of high-precision,gapless precision screws through a synchronous toothed belt to move the middle crossbeam up and down.It has the characteristics of reasonable structure,high rigidity,stable loading,and good stability performance.

3、Technical specifications of testing machine

1.The force sensor is a wheel amplitude tension and compression sensor,with an accuracy of 0.05%FS.The system's force measurement accuracy is within the range of 2%to 100%FS,with a relative accuracy of up to±1%.

2.Electronic extensometer,with an accuracy of Class C,can measure deformation with a relative accuracy of up to±0.5%in the range of 2%-100%FS.(Customers can choose according to the elongation of the material)

3.The displacement sensor adopts a 2000 channel/turn photoelectric encoder and adopts 4x technology to achieve a resolution of 2400 channels/turn(with a maximum resolution of 0.01mm).

4.The deformation measurement adopts an electronic extensometer produced by Beijing Iron and Steel Institute,with a maximum resolution of 0.01mm.

5.The measurement and control system adopts the AD800 testing machine measurement and control system,with the following main indicators:

1)Three analog input channels are used for force value and electronic extensometer measurement,with an AD conversion code of±120000(non segmented measurement achieved with high-resolution AD converter is better than 4-stage amplification).

2)A digital output channel with a 1:100 speed ratio,used to control the servo system for stepless speed regulation within the range of 2-200mm/min.

3)Three optoelectronic coding input channels are used for measuring large deformations and displacements,using quadruple technology to improve measurement resolution.

4)A manual operation box with 8 buttons.

Main technical parameters

Maximum test force 150kN

Accuracy level 1

The allowable error limit of the test force indication is within±1%of the indicated value

Load measurement range 1.2%to 100%FS of full scale

Force resolution 2.1/300000 of maximum test force

Limit error of displacement indication within±1%of the indication value

Minimum displacement resolution of 0.01mm

Cross beam speed adjustment range:0.05-500mm/min

Within±1%of the set value of the relative error in the speed of the crossbeam

Effective test width 450mm

Effective stretching space distance 650mm

The overall size of the host is 795mm x 520mm x 2000mm

The weight of the host is about 400kg

Power supply 220V,50Hz,1.5KW

Software and interactive human-machine dialogue operation interface in the Windows operating environment

The experimental process,measurement,display,analysis,control,etc.are all completed by microcomputers

After the sample is damaged,the moving crossbeam automatically stops moving(or automatically returns to its initial position)

Equipped with two levels of limit protection:programmable and mechanical

Automatic shutdown when the load exceeds the rated value by 3-5%

4、Introduction to Measurement and Control Systems

(1)Circuit Introduction

The AD800 all digital data measurement and control acquisition card is a microcomputer built-in PCI test card based on PCI interface,which complies with the PCIe 2.1 specification.This card can be directly inserted into any PCI slot of the microcomputer,and connected directly to the testing machine through simple wiring to achieve automatic measurement and control of the microcomputer,truly achieving plug and play measurement.The AD800 universal test card integrates functions such as programmable amplification,A/D conversion,digital I/O,counting and pulse width(PWM),square wave generation(SWP),etc.Its system structure is reliable and simple,and it has excellent interchangeability.

(2)Technical performance

a)The entire system adopts digital design,which is safe,stable,reliable,and highly accurate

b)There are no adjustable devices in the entire system,and digital zeroing and automatic calibration of measurement and control parameters

c)The system integrates CPLD computing devices with high-speed computing capabilities and real-time processing of digital signals

d)This system adopts the PCI2.1 bus standard,which is easy to expand,upgrade,and achieve"plug and play"

e)Integrated precision instrument programmable amplifier,automatic shifting and zero detection

(3)Software Introduction

Software main interface

Software data query interface

(4)Software Overview

a)Based on the WINDOWS operating platform,the software is easy to operate,powerful in function,and has a human-machine dialogue structure.Adopting the standard Windows 7 style,the operation is simple and easy to learn

b)The software adopts modular design,with independent modules for creating different types of experiments,controlling experiments,and analyzing data,separated from the main program.Can adapt to various types of experimental control and data processing

c)Experimental data can be added by users themselves,with no limit on the number.New experimental records can be created using templates,which is convenient and fast

d)Automatically complete the test process,determine the type of damage,and automatically record and save test data.All experimental data is saved in internationally recognized XML format

e)Efficient experimental data management function,which can quickly query,load,and delete experimental data in multiple ways

f)At the end of the experiment,the system automatically analyzes and summarizes the experimental results,and the analysis method can be set by the user themselves

g)Flexible report editing function provides users with a specialized report editing tool for graphic layout,which is simple and easy to learn,and can easily print experimental curves,related images,and text

h)Users can delete experimental data as needed

i)Users can change the analysis method as needed,and the data can be modified and rounded according to their own needs

j)Dedicated database management library module

k)Simultaneously record the force time,deformation time,and displacement time test curves,which can be switched and observed at any time,with arbitrary scaling,horizontal or vertical movement,and real-time high-speed sampling

l)Provide multiple report printing interfaces,allowing users to edit reports in any format as needed

m)The experimental data is managed using a standard database,and all experimental data and curves are automatically saved

n)During the experiment,the test curve is displayed in real-time,and after the experiment is completed,the test data,curve,and specimen information of the specimen will be displayed in this operation window.

(5)Partial national standards or test methods for software integration

This control software has now integrated over 100 national standards or testing methods for metals and non-metals,which can meet the diverse testing needs of customers.The testing report methods can be customized and updated according to customer needs at any time,which can bring great convenience to customers.

(6)Data Query Window

Historical experimental data can be queried in the database by entering certain conditions,and the experimental data can be immediately found.

(7)Automatic calibration window

The force value and deformation can be automatically calibrated.After our debugging is completed,if the user feels that the displayed value is inaccurate or the measurement and control parameters have been changed,they only need to click the automatic calibration button,and the system parameters will return to the state they were in during debugging.

(8)The zeroing of the system adopts digital design

With just a mouse operation,two acquisition channels can be zeroed.The system generally only needs to be zeroed once,and under normal use,the system will automatically return to the true zero point.

(9)Batch data processing and batch report printing window

A batch of similar specimens can be summarized and analyzed,and the measurement and control data can be compared and the average value calculated.The specimens can be summarized and printed in batches.We can customize special test reports for customers.These are just a few representatives in various forms.The test report can also be edited and printed according to user requirements,and has relevant processing software(batch processing,control programmer,MaxDoc report processor,MaxX1s report processor,etc.)

5、After sales service

1.Warranty scope

The warranty for the testing machine host is one year(excluding sensors and fixtures),with lifelong service.

2.Maintenance services

1)The consulting service provider can answer any questions about product use by phone or in writing at any time.

2)During the warranty period,the supplier shall provide a troubleshooting plan for the user within 12 hours and notify the user.If it cannot be resolved,the supplier shall send personnel to provide on-site service.

3)During the warranty period,only repair costs will be charged for faults or damages caused by human error or natural disasters.

3.The following situations are not covered by the warranty

1)Malfunctions or damages caused by abnormal operations and human or natural disasters.

2)Damage caused by dismantling and modifying parts(such as microcomputers,hosts,circuits,etc.)without our consent.

3)Without our consent,any installation of virus software,deletion of computer files,or unauthorized use of self registration numbers may cause the testing machine to malfunction.

4.Update services

1)Free upgrade of experimental software for users,with discounts on expanding experimental functions for users.

Users only charge material and processing fees for other attachments purchased from the company,and do not charge management fees.